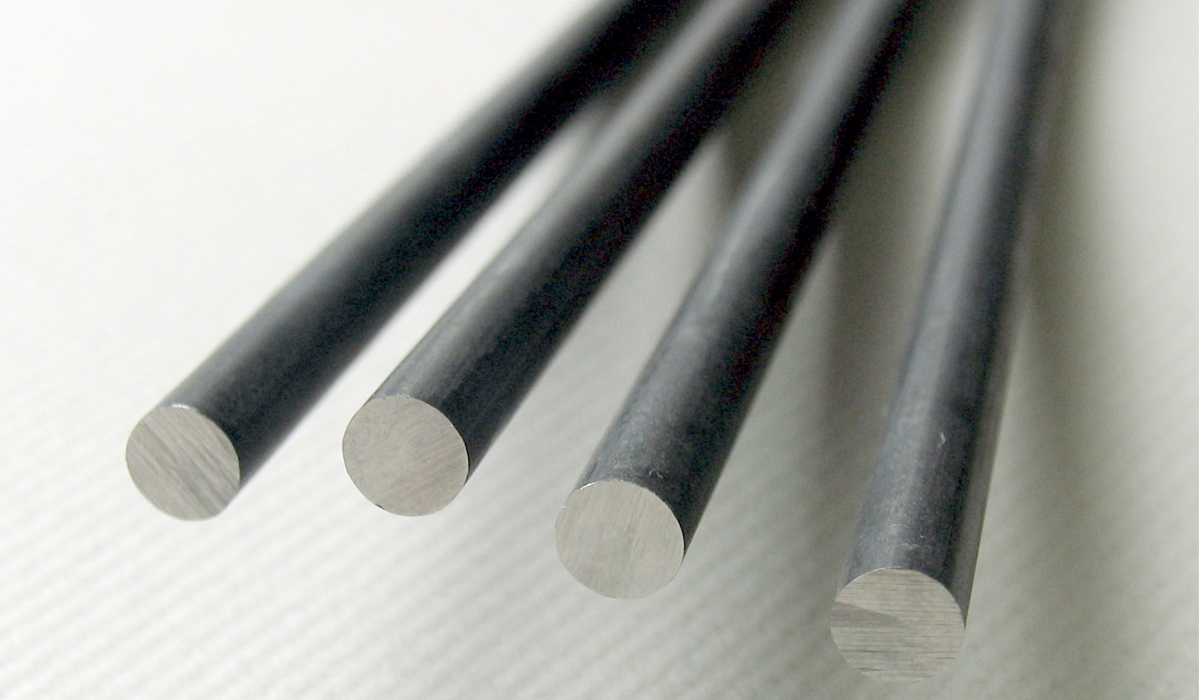

STAINLESS STEEL ROUND BARS & RODS Round Bars & Rods

Specification of Stainless Steel 304/304L/304H Round Bars & Rods

| Grades | Stainless Steel 304/304L/304H (UNS S30400/S30403/S30409) |

|---|---|

| Specifications | ASTM, ASME, AISI A 276 , SA 276, A 479, SA 479 |

| Range | 3 MM TO 350 MM DIA |

| Finish | Bright, Polish & Black |

| Form | Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

Chemical Composition of Stainless Steel 304/304L/304H Round Bars & Rods

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

|---|---|---|---|---|---|---|---|---|---|

| SS 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18 - 20 | - | 8 - 11 | - |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 - 20 | - | 8 - 13 | - |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 - 20 | - | 8 - 10.5 | - |

Mechanical Properties of Stainless Steel 304/304L/304H Round Bars & Rods

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35% |